|

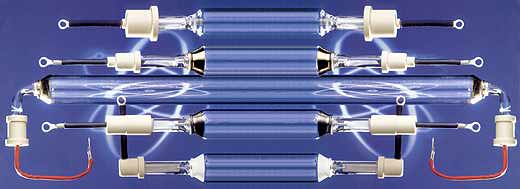

Standard Mercury UV LampsOur UV curing lamps are medium pressure Mercury Vapor lamps that are fabricated from a pure grade of amorphous non-crystalline silicon dioxide (SiO2) with tungsten electrodes sealed in each end by experienced craftsmen on specialized lathes. It is this mix of experience, equipment, and materials combined with a unique construction technique which yields a lamp of the highest quality and reliability. Extended Life versions offer life 2 to 3 times typical lamps. UV curing lamps vary in arc length from 1 inch to 180 inches. Short Arc Lamps (with arcs of 11mm to 1.5mm) are also available. Typical power levels range from 200 to 1000 watts per inch, Super UV Lamps operate at 400 WPI and above. Metal Halide lamps are available in several different spectra. The most common arc lamp for curing contains mercury. |

Spectrum |

Special ballasts are required for metal halide lamps. These ballasts have a higher open circuit voltage and special output waveform (crest-factor). This feature also extends lamp life while keeping the mercury and heavy metals within the lamp structure in a plasmatic state during temperature and voltage variations.

| Metal halide lamps are used in many types of applications whose photochemistry requires different UV wavelengths to initiate the photo-polymerization process. These come in either Gallium-Indium or Iron -Cobalt. Other additives are available upon request. |  Spectrum |

Spectrum | Note that the Iron-Cobalt lamp has a broader spectrum with more spectral output in the 380 to 390nm region. The Gallium-Indium has an enhanced output in the 403 to 420nm region. |

| Another mix show to the right is a multi-spectrum lamp which is a mixture of Iron-Gallium producing an increased output over a broader region. |  |

The combination of improved electrodes and the internal fill mixture results in a lamp which extends electrode life, therefore yielding a cleaner longer lasting lamp with less UV drop off. If you presently have a ballast and want to confirm the compatibility of extended life lamps, please fill in ballast operating and striking voltage in comments section of lamp RFQ form.

Note that no additional electrical input power is required, lamps will operate on most standard mercury vapor ballasts. The lamps use a two millimeter quartz wall thickness (24 millimeter minimum outside diameter) and are warranted for 500 hours unconditionally. A typical 400 watt per inch Super UV lamp will equal or out-perform a standard 600 watt-per-inch mercury lamp while having the infrared radiation of a 400 watt-per-inch lamp.

Efficiency vs Watts per Inch |

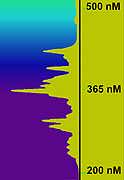

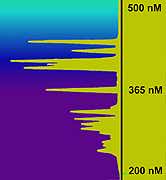

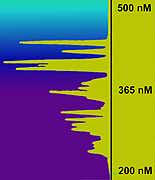

Total radiation efficiency in terms of UV energy output is affected by the operating power level of the lamp. For example a 400 watts-per-inch lamp will more than double the cure rate when compared to two lamps running at 200 watts per inch each. The spectral chart below shows a comparison of the ultraviolet output of the same voltage lamp operated at 200, 300, 400 and 600 watts per inch by varying the secondary current applied to the lamp |